Thermal properties

Plastics have versatile thermal properties, including insulation and heat resistance, thus making them materials that easily adapt to many different applications.

Do you work with plastics and need to quantify or measure their thermal properties? Properties such as thermal conductivity, thermal expansion and sealability can be decisive when choosing a material for a specific application.

Thermal properties testing

The AIMPLAS laboratories contain a wide range of equipment designed to measure the thermal behaviour of polymeric materials in order to choose the right material, based on its application, to produce packaging, materials for the construction and automotive industries, and medical devices.

1. Thermal conductivity

We evaluate the material’s ability to conduct temperature from one of its surfaces to another. Applicable standard: UNE-EN 12667.

2. Dynamic-mechanical analysis (DMA)

In polymers, this technique is used to study the mechanical and thermal properties of polymeric materials. The test measures the material’s response to the application of a sinusoidal stress as a function of temperature or time.

The information obtained from the test includes relevant parameters such as the storage modulus, loss modulus and loss factor, which are important indicators of the material’s stiffness, elasticity and energy dissipation capacity. These data are useful for understanding the mechanical behaviour of polymers under different conditions and can be used to choose and design materials for different applications.

3. Vicat softening temperature

This technique is used to measure the thermal resistance of polymeric materials. The temperature is increased at a constant rate and the temperature is measured at which the material begins to soften when the surface is penetrated by a needle. This test indicates the temperature at which the material loses its stiffness and becomes more deformable. At AIMPLAS, we are accredited to carry out tests in accordance with standards UNE-EN ISO 306 and ASTM D1525.

4. Heat deflection temperature (HDT)

The HDT test is useful for understanding the thermal behaviour and resistance to deformation of polymeric materials and for selecting and designing materials for different applications, such as automotive parts, electronic components and household items. It helps to determine the temperature at which a sample deforms to a specified degree under a load applied at constant heat.

At AIMPLAS, we are accredited to carry out tests in accordance with standards ASTM D648, UNE-EN ISO 75-1 and UNE-EN ISO 75-2.

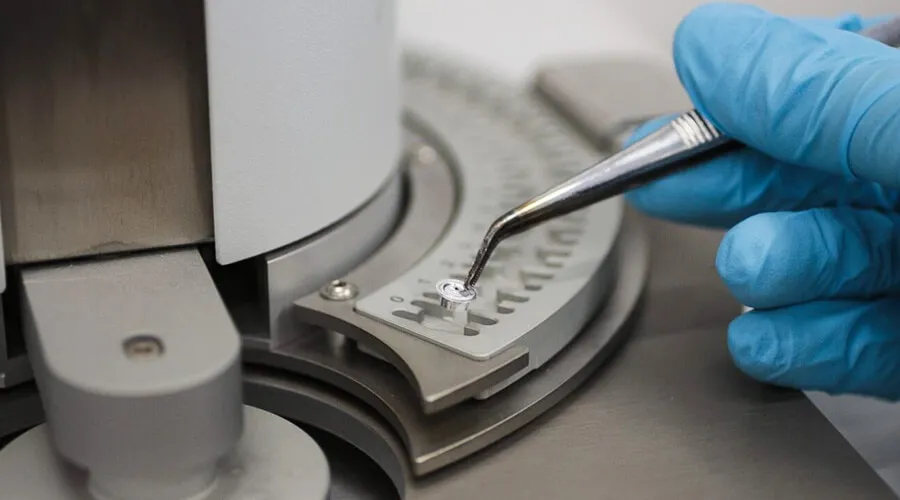

5. Differential scanning calorimetry (DSC)

Thermal analysis is defined as the set of techniques used to measure a material’s physical or chemical properties as the temperature of the sample changes.

Of the different techniques included within the concept of thermal analysis, differential scanning calorimetry (DSC) can be considered the fundamental technique for thermal characterization of polymer systems. In this technique, the test sample is exposed to a temperature-controlled programme and the difference between the energy absorbed or released is measured.

6. Thermogravimetric analysis (TGA)

This test measures the variation of mass of a sample material as temperature rises at a constant rate. Weight loss takes place when the volatile compounds absorbed by the sample evaporate at low temperatures and due to polymer degradation at high temperatures.

AIMPLAS has the highest number of tests accredited by ENAC (Spanish National Accreditation Body) for plastics according to the UNE-EN ISO/IEC 17025 standard in Spain.

We provide added value to our clients through a close relationship, advice on the interpretation of results and the preparation of clear and understandable reports.

AIMPLAS ensures the best results and quality for its clients so that companies can guarantee the reliability of their products or services