Mechanical properties

Determining the mechanical properties of materials is, in many cases, essential when selecting one material or another on the basis of its performance.

Do you need to quantify or measure the mechanical properties of your plastic material? Mechanical properties are often the most important because almost all service conditions involve a mechanical load.

Mechanical properties are related to forces outside the material that are applied to it and respond in one way or another depending on the type of polymer and the transformation process it has gone through. Generally, plastic materials usually respond to the forces they are subjected to, being deformed to a greater or lesser extent, and possibly ending up in breakage.

Testing of mechanical properties

AIMPLAS offers you different solutions to determine the mechanical properties of a plastic material. Different mechanical properties can be determined depending on the need and the field of application of each product, such as the packaging, construction or automotive industries.

The most commonly used equipment to assess the stress-strain behaviour of materials is the Universal Testing Machine (UTM), with which we can determine tensile, compression, and tearing properties:

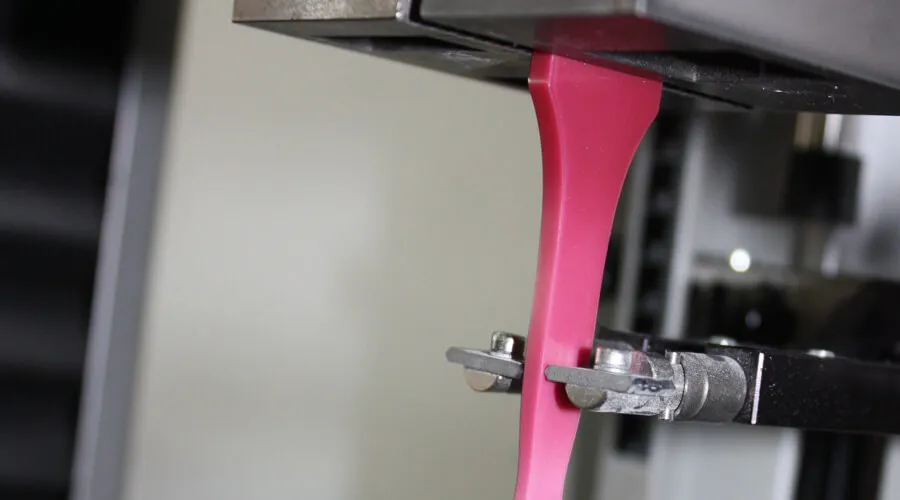

1. Tensile properties

This involves applying stress in the same direction as the longitudinal axis of the test specimens. The general standard for plastic materials is UNE-EN ISO 527. A graph can be obtained with the recorded stress-strain data, from all the tensile tests performed on the universal testing machine, from which the elastic and plastic behaviour of a material can be determined and its maximum tensile strength or stress at break can be quantified.

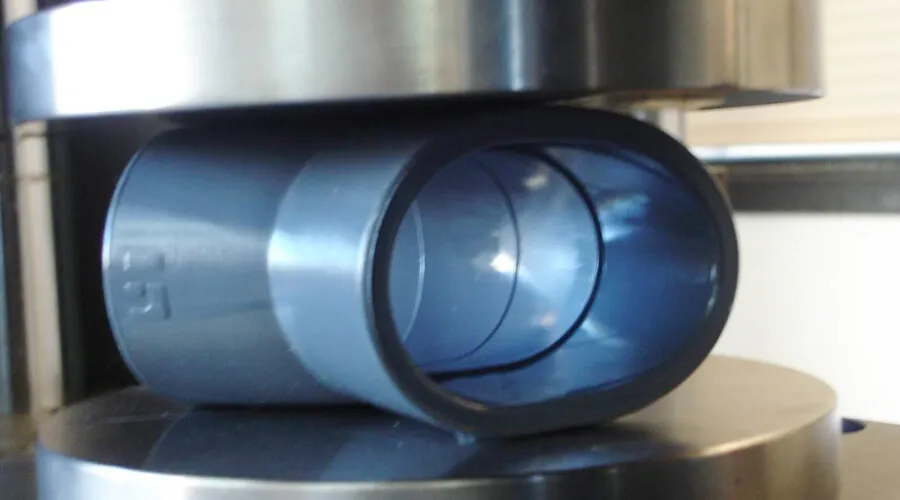

2. Compression properties

They describe the behaviour of a material when it is subject to a compression load at a uniform speed. The general standard for plastic materials is UNE-EN ISO 604. In practice, compression loads are not always applied immediately. Compression tests are a method to obtain results in research and development, quality control and acceptance or rejection, according to the specifications. In some cases, in order to study the compression behaviour of some products, tests are performed on the complete product itself, without the need to machine a smaller test specimen. This kind of study is very common in packaging products such as bottles, trays and containers. Normally, in these cases, standard UNE 12048 is used.

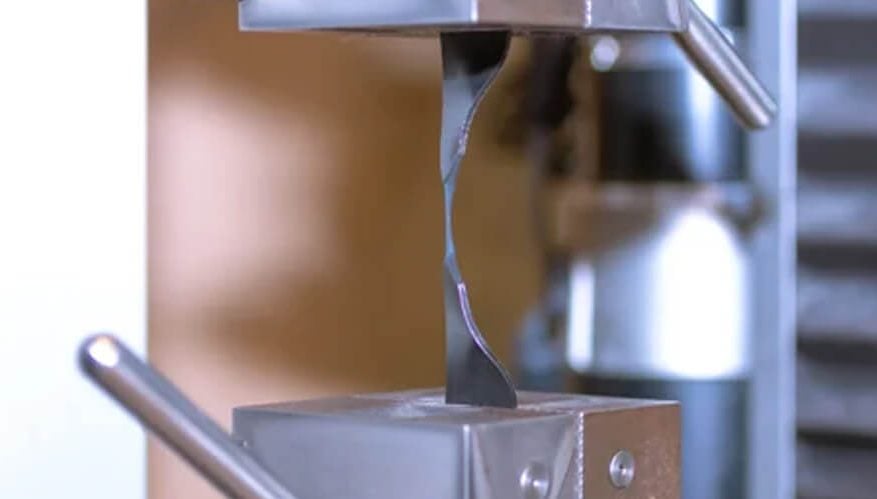

3. Flexural properties

This is the ability of a material to withstand stress applied in a perpendicular way to its longitudinal axis. The stresses at the maximum and fracture points, the corresponding deformations and the flexural modulus are calculated considering the distance between supports based on the test specimen’s thickness. The general standards used are UNE-EN ISO 178 for plastic materials and UNE-EN ISO 14125 for fibre-reinforced plastic materials.

4. Static and dynamic friction coefficients

These are determined in accordance with the UNE-EN ISO 8295 standard for plastic materials using plastic film (films). They are the ratio between the tensile strength required to initiate or continue sliding at the interface between two surfaces and the force of gravity acting perpendicularly on them.

5. Peeling tests

This is a testing method used to determine the bond strength of plastic materials in films, sheets and plates. It is applicable to the study of any type of bond, regardless of the method used (sealing, adhering, stitching, multi-layer bonding, etc.).

6. Puncture testing

This is used for films and sheets although it is also used on thermoformed packages. The general standard used is UNE-EN 14477. Other standards, such as UNE-EN 12236, are used for other types of materials, such as waterproofing sheets. Normally, the name given to this test is static puncture rather than just puncture.

7. Tear test

The tear test is used to determine the force required to propagate the tear of a defined cut from a cut made in a test specimen or a test specimen with a defined notch. The general standards used are UNE-EN 6383-1 and UNE-ISO 34-1. There are other standards that refer to tear tests that are applied more specifically to plastic films and that follow similar standards, such as UNE-EN ISO 6383-2 for Elmendorf tear testing. The Elmendorf tear resistance is a property that is determined in plastic films and sheets normally for use in the packaging industry.

8. Hardness tests on plastics

This is the resistance of a material to scratching or penetration. It is a measure prior to fracture and is a function of both the rigidity of the material and its modulus of elasticity. There are different methods to determine the hardness of a plastic material, such as the Shore, Barcol or ball methods, which are determined with testing standards UNE-EN ISO 868, UNE 53270 and UNE-EN ISO 2039-1, respectively.

9. Impact testing

This encompasses free fall, falling dart and pendulum impacts such as Charpy and Izod. Depending on the type of material to be studied, the type of test specimen will be different. The difference between these tests and the mechanical tests performed with the UTM is the test speed. In these cases, higher speeds are used.

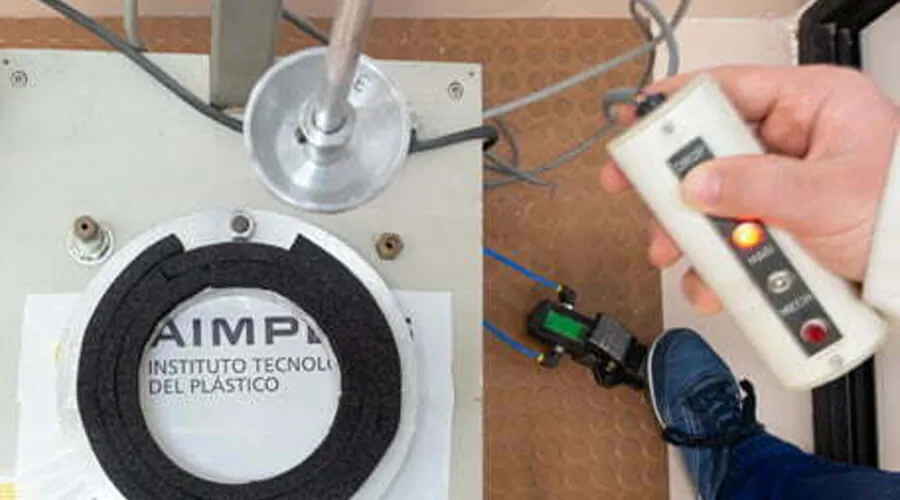

AIMPLAS has the highest number of tests accredited by ENAC (Spanish National Accreditation Body) for plastics according to the UNE-EN ISO/IEC 17025 standard in Spain.

We provide added value to our clients through a close relationship, advice on the interpretation of results and the preparation of clear and understandable reports.

AIMPLAS ensures the best results and quality for its clients so that companies can guarantee the reliability of their products or services