Emission tests in car interiors

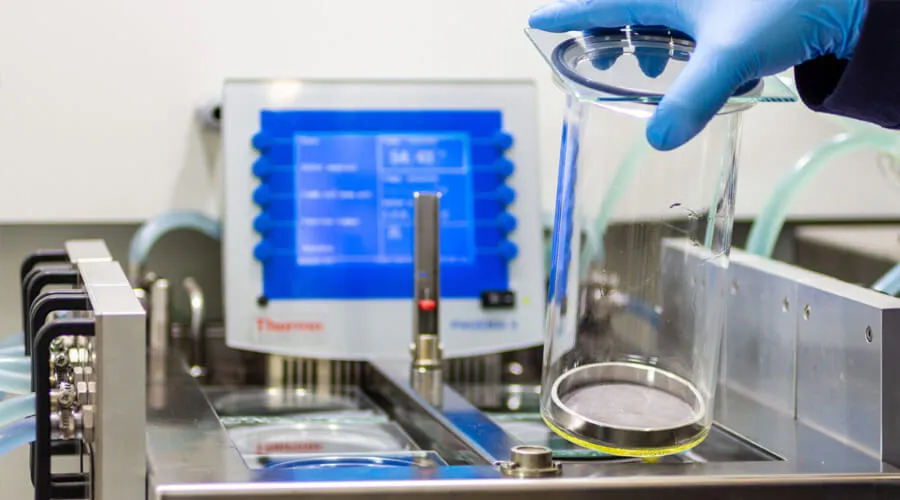

Analysing emissions from plastics inside the vehicle is essential to ensure the quality of the interior air and the health of the occupants.

Air quality in car interiors has represented a matter of serious concern for the automotive industry since the late 1970s due to the effect of volatile organic compound (VOC) emissions on human health and consumers’ potential rejection as a result of the odours emitted by plastic components inside vehicles.

For this reason, components must comply with highly restrictive standards that require an assessment of the emissions from the plastic materials used in car interiors at various levels: raw material, part and vehicle.

In our laboratories, we determinate volatile substances that may be emitted by various materials inside vehicles such as plastics, textiles and leather. These tests are carried out in accordance with the specific standards of the main manufacturers, including VW/Audi, BMW, GM, PSA Peugeot Citroën, Ford, Toyota, Saab, Porsche and Daimler.

Emission tests we offer

Total volatile organic compound and carbon emissions (TVOC)

The emission of different VOCs by some plastic components inside vehicles in large and uncontrolled quantities can make the passenger cabin an exposure area for users, thus leading to health and well-being issues.

Car manufacturers make significant efforts in terms of research to minimize COV limit values and perform tests to assess the presence of COVs in car interiors and thus guarantee people’s safety.

Total volatile organic compound (TVOC) tests not only analyse the VOCs emitted by materials and ensure that they do not exceed the values required by manufacturers, but also identify the substances emitted and their levels and assess whether they are included on the list of substances prohibited by manufacturers.

Standards: VDA 277, PV 3341, STD 1027,2714, VCS 1027,2749 and FLTM BZ 157-01.

Volatile organic compound emissions by thermal desorption (VOCs)

VOC testing can also be conducted with other analytical methods, depending on the manufacturer’s requirements.

Analysis by thermal desorption is used to determine two semi-quantitative cumulative values that make it possible to estimate VOC and FOG (condensable substances) emissions. This determination is carried out after two different heating cycles in which the compounds are thermally extracted and condensed in a cold trap and then injected into a chromatographic system (GC-MS) for semi-quantification and identification.

Standards: VDA 278, D10 5495, D42 3109, GMW 15634, etc.

Emissions of formaldehyde and other aldehydes and ketones

Formaldehyde, a product that is produced by the degradation of polyoxymethylene (POM) and is found in adhesives and textile and insulation treatments, is a highly volatile substance that can cause irritation of the tissues (eyes, throat, nose, lungs, etc.) and can even cause more acute complaints such as lung cancer when certain levels are inhaled. This substance and other aldehydes (acrolein, acetaldehyde, benzaldehyde, hexanal, etc.) and ketones (ethyl methyl ketone and acetone) must be controlled in plastic materials used in car interiors.

Aldehyde and ketone emissions are determined after the material is subjected to controlled heating and the aldehydes and ketones emitted are analysed. Depending on the manufacturer’s requirements, this assessment can be conducted by means of two different methodologies: liquid chromatography with a UV detector or UV spectrophotometry.

Standards:

- Spectrophotometry: VDA 275, PV 3925 (part B), FLMT BZ 156-01 (part A), VCS 1027,2739, STD 1027, 2713, etc.

- Chromatography: PV 3925 (part A), FLMT BZ 156-01 (part B), GMW 15635, D40 3004/–A, D40 5535, etc.

Odours

Controlling the emissions from materials used in car interiors is required because of the effect they can have on the health of users. Odour is therefore a mandatory parameter that must be checked by car manufacturers.

This analysis is carried out by a panel of qualified experts who have been trained to assign odour intensity to the materials used in vehicle interiors under climatic conditions (temperature, time, humidity and sample size), which depend on the requirements of the manufacturer.

Standards: VDA 270, FLTM BO 131-03, GMW 3205, PV 3900, VCS 1027,2729, TPJLR.52.458, SAE J1351, etc.

Fogging or condensable substances

Under certain conditions, volatile substances present in plastic materials inside vehicles occasionally condense and fog the glass of the car, which can make driving hazardous.

Fogging or condensable substance tests assess condensation in glass contained in the materials used for car interiors by means of two different methods that subject the material to heating: photometry and gravimetric analysis.

Standards: DIN 75201, SAE J 1756, ISO 6452, PV 3015, PV 3920, STD 420-0003, GMW 3235, VCS 1027, 2719, D45 1727-H, etc.

Find out more »

Emissions in the one-cubic metre chamber

Emissions analysis using a one-cubic metre dynamic chamber is used to validate large parts under conditions similar to real life while controlling heating time, temperature, humidity and airflow.

In accordance with manufacturers’ specific standards, emissions of aldehydes, VOC, fogging and odour can be assessed after the sample heating period.

Standards: VDA 276, PV 3942, GS 97014-3, ISO 12219-4, VCS 1027, 2769, etc.

How we do it

AIMPLAS’ laboratories are accredited by ENAC in accordance with standard UNE-EN ISO/IEC 17025:2017 to perform all the above-mentioned emissions tests and are the first Spanish laboratories to obtain accreditation to carry out odour tests, emissions testing by thermal desorption (VOC/FOG) and emissions testing using chambers.

AIMPLAS’ laboratories are also included in the list of laboratories approved by Volkswagen Group to analyse TVOCs, fogging and formaldehyde; by Renault to analyse fogging and by Daimler to analyse odour. In this regard, AIMPLAS’ laboratories are continuing to work towards incorporating new tests, such as emissions with the bag method and being approved by other manufacturers and test standards.