Identification and chemical analysis

Do you need to characterize an unknown sample? Check compliance with specifications, regulations or legislation? Obtain a technical data sheet of your product? Identify the cause of a defect or abnormal behaviour? Ascertain the nature of a contaminant?

Polymer and plastics chemical analysis

AIMPLAS offers you different solutions for all of your chemical analyses in terms of raw materials, finished products and recycled materials regarding polymers, additives, residual substances, contaminants and impurities. Thus, AIMPLAS covers the whole plastics value chain.

- Composition of a plastic material

- Characterization of multilayer and printed films

- Verification of specifications in pipes and their raw materials

- Verification of specifications for the automotive industry

- Analysis of painted or coated parts

- Characterization of resins and thermoset composites

- Analysis of recycled plastic materials

- Identification/quantification of additives

- Impurity and contaminant analysis

1. Composition of a plastic material

By combining different analysis techniques, we can obtain the composition of an unknown plastic material, thus identifying which polymer or polymers, mineral fillers and reinforcements are present. Likewise, the percentage of these mineral fillers. This information is very useful to ensure compliance with the requirements needed to obtain the technical data sheet of a material, to find out the possible causes of failure in the transformation process or in usage, etc.

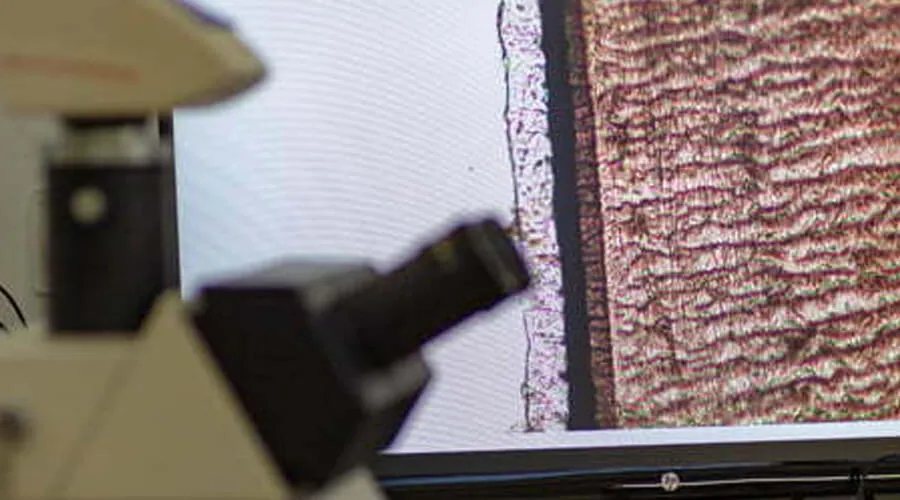

2. Characterization of multilayer and printed films

We characterize multilayer films and identify which polymers are present, how many layers the material has, their thickness and which materials make up each layer. This information allows us to compare different products, verify that the structure is as expected, and find out about any unexpected behaviour of a material during its processing or shelf life. Some of the problems we have solved in this area are delamination in packaging films and sealing problems.

On the other hand, in the case of materials subject to lamination in solvent-based printing processes it is essential to determine the level of solvents that may remain in the material after drying processes, so that they do not affect the organoleptic properties of the final product.

3. Verification of specifications in pipes and their raw materials

Plastic pipes used in the construction sector must comply with certain requirements to obtain product certification. In this regard, we perform carbon black content tests, carbon black dispersion tests, Oxidation Induction Time (OIT), and gelation time in PVC, among others, all aimed at ensuring a minimum percentage that enables compliance with the required technical requirements. In addition, we determine the degree of cross-linking and the gel content in PE-X pipes, as well as in any other cross-linked materials.

4. Verification of specifications for the automotive industry

In the automotive industry, every part must be validated by means of strict quality control tests through the verification of critical parameters, that guarantee their functionality and user safety. Some important parameters are melting temperature; identification by infrared spectroscopy, glass fibre, ash or moisture content, since these have a significant influence on the material’s final behaviour. Another important aspect for this sector is to ensure that volatile substance emission limits are complied with in plastic parts to be used inside vehicles. In this sense, we analyse odour emissions, Total Volatile Organic Compounds (TVOC), fogging or condensable substances, formaldehyde, etc.

5. Analysis of painted or coated parts

To verify specifications or to investigate possible reasons for the appearance of surface defects or poor adherence of a coating or paint, we analyse parts, substrates and coatings by optical or electronic microscopy that allow the close-up visualization of faults and the morphology of materials. Furthermore, studies can be completed by elemental analysis to detect the presence of elements that do not belong to the material included in the part or its coating.

6. Characterization of resins and thermoset composites

Thermosetting resins are characterized by means of tests such as the determination of the curing curve, gel time, density, acid index, hydroxyl value and solids content, which give information about curing process behaviour.

In addition, resin types can be identified to check which family they belong to, thus obtaining valuable information to complete the cause of failure analysis in thermoset composites, such as GFRP pipes and other products. The analysis of a thermoset composite can be completed by determining its fibre glass or textile glass content, either to check technical compliance, or as part of a study to analyse causes of failure or to characterize an unknown sample.

Another interesting parameter is the residual styrene content of thermoset composites, as this is directly related to the degree of curing of the material, and therefore to its correct functionality. The higher the degree of curing, the lower the presence of residual styrene in the product.

7. Analysis of recycled plastic materials

As recycled materials come from different sources, they must meet quality standards that ensure correct processing and functionality of the finished product. A series of international standards have been developed to facilitate this task, defining the required and optional characteristics to be established, and the specifications and test methods applicable to each type of material. These tests include a composition analysis of polymers and other materials to ascertain the level of contaminants, fine particle content, mechanical and rheological properties, etc.

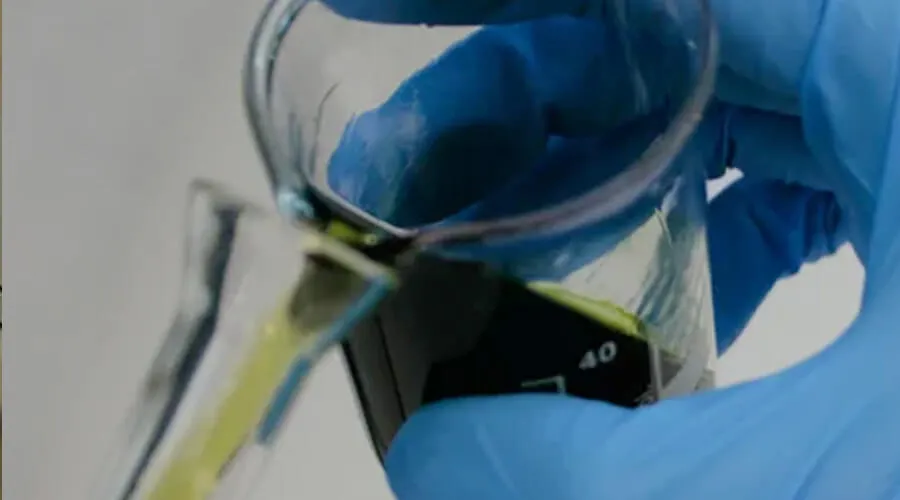

8. Identification and quantification of additives

Sometimes there is a need to verify whether a plastic product contains the right additives for its intended purpose, e.g. when premature degradation is observed when exposed to solar radiation, or when blockage occurs between films during processing or subsequent food packaging. In other cases, it is necessary to confirm that certain additives regulated by legislation are not present, as is the case with plastic materials that come into contact with food. Various instrumental techniques are applied, mainly using chromatographic methods, which enable the additives to be analysed after being isolated from their polymeric matrix. In general, these techniques are useful for analysing additives such as antioxidants, UV stabilizers, plasticizers, antifogging agents, anti-slip agents, etc.

9. Impurity and contaminant analysis

If you need to find out the exact composition of a foreign body found in food or in a plastic bottle, or a residual substance deposited in a filter somewhere along the industrial process, we can help you by analysing the sample to establish whether it is a polymer from the degraded material, or from the container the food was packed in, or from the pipes the material flowed through, or from the rubber seals in an installation. These are typical laboratory research cases in which the in-depth knowledge of experts is applied in combination with diverse instrumental techniques such as spectroscopy, thermal analysis and microscopy.

Our laboratories

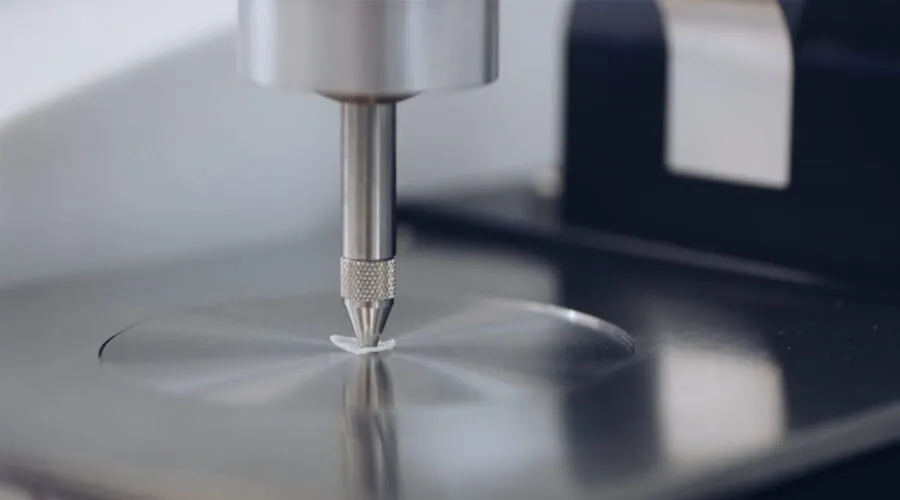

AIMPLAS’ laboratories have a wide variety of equipment and instrumental techniques available. The laboratories are staffed by our highly experienced specialists who are on hand to carry out the analyses and tests mentioned above:

- Thermal analysis: DSC, TGA, DMA.

- Spectroscopy: FTIR, Raman, UV-visible.

- Microscopy: optical and electron (SEM).

- Elemental analysis (EDX coupled with SEM).

- Chromatography: GC-FID, GC-MS, GC-NPD, HS-GC-FID, HPLC-PDA, LC-MS, LC-LS, GPC.

- Water content analysis (Karl-Fischer).

AIMPLAS has the highest number of tests accredited by ENAC (Spanish National Accreditation Body) for plastics according to the UNE-EN ISO/IEC 17025 standard in Spain.

We provide added value to our clients through a close relationship, advice on the interpretation of results and the preparation of clear and understandable reports.

AIMPLAS ensures the best results and quality for its clients so that companies can guarantee the reliability of their products or services