Fire

Evaluating the fire behavior of plastic materials is crucial to ensure safety and prevent risks.

One of the typical characteristics of all plastics is their low fire resistance. The demand for self-extinguishing materials is increasing due to the need to offer higher safety levels.

UL94 Classification

UL94 classification is a flammability rating standard for plastics developed by Underwriters Laboratories (UL). This system assesses the fire response of plastic materials based on their self-extinguishing properties. UL94 categorizes materials into different groups based on their ability to resist flame propagation and the formation of glowing droplets. These classifications are important for evaluating the safety of plastic materials in various applications, such as the manufacturing of electronic components and other products.

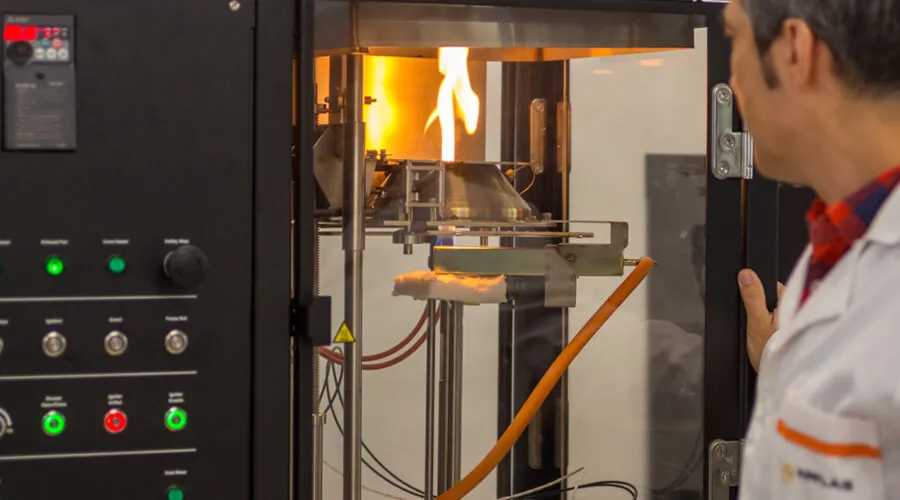

Types of flammability tests

There are two types of flammability tests according to UL 94: horizontal and vertical, which consist of measuring the burning time of a plastic sample fixed horizontally or vertically, after it has touched the flame of a burner during the time specified in the corresponding standard.

- Horizontal Flammability · automotive sector

A specific flammability test is carried out for the automotive sector under international regulations and specifically adapted by the main vehicle manufacturers: Ford, Volvo, Opel, Nissan, VW, etc. This Horizontal Flammability test evaluates the fire resistance of materials inside a car and affects all non-metallic materials that are used in the manufacture of parts located in car interiors. The maximum speed of flame propagation in these materials is standardised and established by most vehicle manufacturers at a maximum of 100 mm/min.

Cone calorimeter

This device is used to determine:

- heat release rate,

- ignition time,

- smoke production rate,

- mass loss rate,

- release rate of toxic gases (e.g. CO, CO2).

This makes it possible to evaluate materials used in industries such as the maritime sector (IMO 2010 FTP Code Part 2, IMO-Resolution MSC.307 (88)), the railway industry (EN 45545-2), the furniture industry (ASTM E1474), the electrical device sector (ASTM D6113) and the construction industry (ASTM E1740), not to mention the field of research and development of plastic materials for the construction industry.

Applicable standard: ISO 5660-1

Limiting oxygen index (LOI)

This method is used to determine the minimum fraction of oxygen in a mixture with nitrogen that will support the combustion of small specimens arranged vertically under specific test conditions. The result is the limiting oxygen index.

Applicable standard: UNE-EN ISO 4589-2.

Thermal conductivity

The material’s ability to conduct temperature from one of its surfaces to another is evaluated.

Applicable standard: UNE-EN 12667.

Comparative tracking index (CTI) of solid insulating materials (resistance to forming conductive paths)

The tracking test equipment takes measurements to determine the degree of protection against the formation of conductive paths on solid insulating materials. Tracking phenomenon, i.e. the formation of conductive paths, may be due to electrolytic contamination of the surface or moisture on the surface of these materials.

The tests for measuring the formation of conductive paths in accordance with standard IEC 60112 involve applying voltages of 100 V to 600 V. However, with AIMPLAS equipment, voltages of more than 1000 V can be applied.

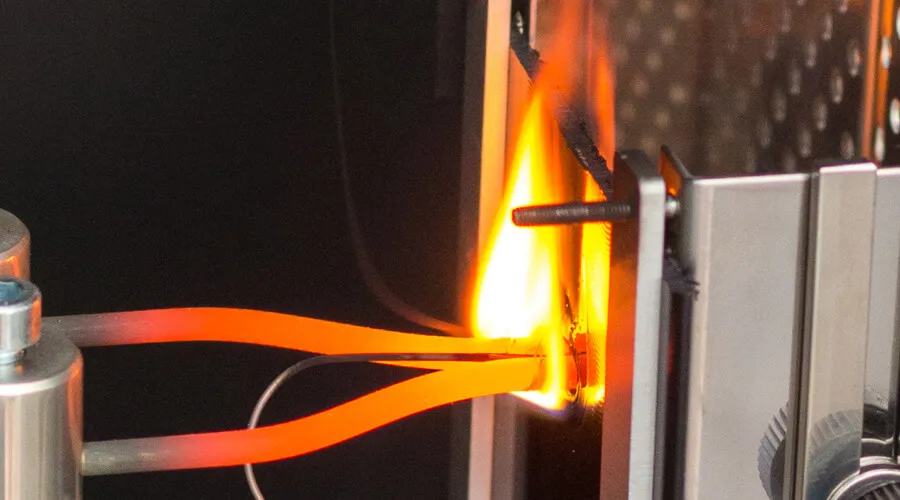

Glow wire tests (GWIT, GWFI)

These tests are used to determine the temperature (between 550°C and 960°C) at which a glow wire in contact with a specimen ignites. If the specimen ignites, it should self-extinguish any flames in less than 30 seconds after the ignition source is removed.

Applicable standards: UNE-EN 60695-2-10, UNE-EN 60695-2-11, UNE-EN 60695-2-12 and UNE-EN 60695-2-13.

Normativa aplicable: UNE-EN 60695-2-10, UNE-EN 60695-2-11, UNE-EN 60695-2-12 y UNE-EN 60695-2-13.

AIMPLAS has the highest number of tests accredited by ENAC (Spanish National Accreditation Body) for plastics according to the UNE-EN ISO/IEC 17025 standard in Spain.

We provide added value to our clients through a close relationship, advice on the interpretation of results and the preparation of clear and understandable reports.

AIMPLAS ensures the best results and quality for its clients so that companies can guarantee the reliability of their products or services