Optical properties

Plastics have versatile optical properties, which range from transparency to opacity, so they adapt to several applications.

Do you need to quantify or measure the optical properties of your plastic material or the surface finish of a part?

Determining the optical properties of materials is essential to define how they are perceived by the senses of sight or touch in order to assess their functionality from an aesthetic point point of view. In addition, through these properties, we can also verify whether a material can retain heat or transmit solar radiation and check whether it is suitable for its intended use.

Testing of optical properties

At AIMPLAS, we can offer different solutions to determine the optical properties of a plastic material. Optical properties can be determined depending on the need and the field of application of each product, (packaging, construction, rubbish bags, automotive plastics, etc.). Some of the properties tested are:

1. Turbidity

Turbidity

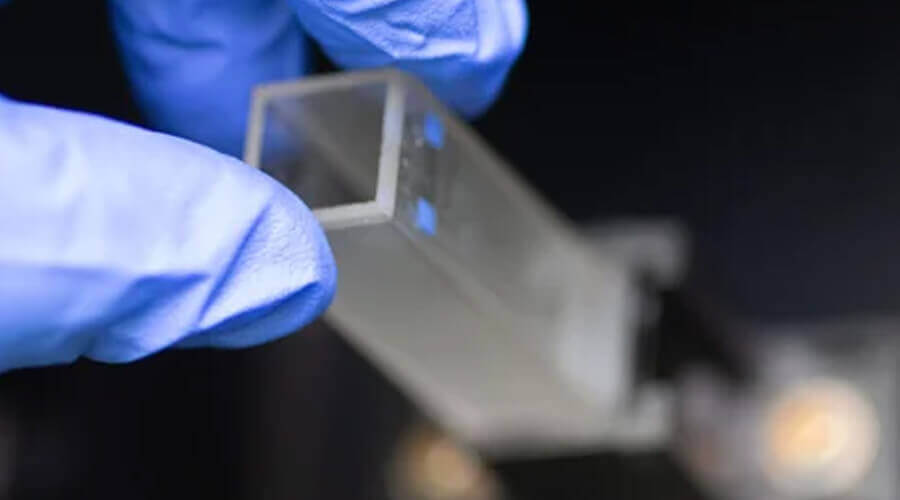

This is associated with the light scattering produced by the accumulation of tiny particles within the material or by very small surface defects. It is tested according to ASTM D1003 and UNE-EN 2155-9 and requires flat sections of transparent plastic materials. It provides the ratio between the intensity of scattered light and incident light.

2. Specular gloss

This is associated with the ability of a surface to reflect more light in some directions than in others. It is determined according to the standards UNE 53036:2001, ASTM D2457 and UNE EN ISO 2813:2014, among others. The intensity of the light reflected at a specific angle (20º, 45º and 60°) is measured by means of a photodetector.

3. Colour coordinates

This is always associated with visual experiences and their interpretation through the human eye is always subjective. In order to avoid this subjectivity and to be able to express colour in numerical terms and guarantee an objective description of the colour of objects, we use spectrophotometers using the colour components L*, a*, b* included in the system recommended by CIELAB, which is the most widely used and recognised system.

AIMPLAS has different equipment to measure colour in different shapes following international standards or different manufacturer standards.

4. Thermicity (IR effectiveness)

This is the capacity of a greenhouse film to retain the heat that dissipates at night thus slowing down nocturnal heat losses and, consequently, reducing excessive drops in temperature inside a greenhouse, and preventing them from affecting the quality or viability of the crops. Thermicity is determined by means of infrared spectroscopy, according to the UNE-EN 13206 standard, obtaining the transmittance value.

5. UV-visible light transmission

This is the ability of a plastic material to allow light to pass through it in the UV-visible range, measured by spectroscopy. Objectives here may be different and even totally opposite. For example, in agricultural film, plastics must allow maximum transmission of visible radiation and minimum ultraviolet radiation transmission. In opaque pharmaceutical and cosmetic packaging, the material must ensure minimum radiation transmission.

Colour consistency and surface defects

These optical properties are specific to solid surfaces, and are determined by visual methods, according to the procedures indicated in the UNE-EN ISO 19712-2 standard, entitled “Decorative solid surfacing materials – Part 2: Determination of properties – Sheet goods”.

AIMPLAS has the highest number of tests accredited by ENAC (Spanish National Accreditation Body) for plastics according to the UNE-EN ISO/IEC 17025 standard in Spain.

We provide added value to our clients through a close relationship, advice on the interpretation of results and the preparation of clear and understandable reports.

AIMPLAS ensures the best results and quality for its clients so that companies can guarantee the reliability of their products or services