Fogging test

It is a crucial test for assessing and controlling the release of volatile substances in materials used in vehicles and enclosed spaces.

Fogging is the effect produced by condensation of the gases of different volatile organic compounds (VOCs), which can evaporate from trim materials in vehicle interiors.

The presence of VOCs in these environments must be limited, which is why assessing all interior and air ventilation system materials is of extreme importance.

The fogging characteristics of trim material in vehicle interiors are determined by means of a test procedure that can be performed using two different methods: Method A, the photometric method, and method B, the gravimetric method.

Methods for the determination of fogging characteristics

Photometric method

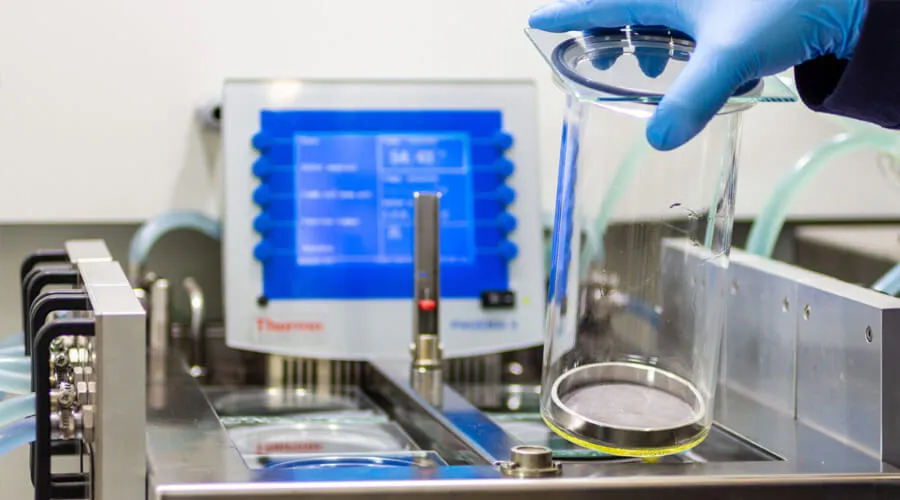

Method A (photometric method) quantifies fogging by measuring the specular gloss to determine the change in the 60º reflective index before and after the test sample is placed in a beaker sealed with a piece of cooled glass and the bottom of the beaker is placed in a controlled temperature oil bath for a specified period of time.

Gravimetric method

Method B (gravimetric method) calculates fogging by using a disk of aluminium foil instead of the piece of glass to seal the beaker with the test sample inside. The disk is weighed before and after the test to determine the change in weight.

The controlled heating unit has different holes to hold the beakers with the test sample inside.

Applicable standards for fogging test

The determination of fogging characteristics is performed in accordance with the following standards:

- ISO 6452. Rubber- or plastics-coated fabrics — Determination of fogging characteristics of trim materials in the interior of automobiles.

- DIN 75201. Determination of the fogging characteristics of trim materials in the interior of automobiles.

- SAE J1756. Determination of the Fogging Characteristics of Interior Automotive Materials.

- PV 3015. Non-Metallic Materials for Interior Trim – Determining Condensable Constituents (Gravimetric method).

- PV 3920. Non-Metallic Materials for Interior Trim – Determining Condensable Constituents (Photometric method).

- STD 420-003. Fogging. Organic materials.

- GMW 3235. Fogging Characteristics of Trim Materials.

- VCS 1027,2719 Fogging.

- D45 1727. Interior trim materials and cockpit parts fogging – misting.

All these standards fall within the scope of AIMPLAS’ ENAC accreditation of automotive laboratories.

AIMPLAS has the highest number of tests accredited by ENAC (Spanish National Accreditation Body) for plastics according to the UNE-EN ISO/IEC 17025 standard in Spain.

We provide added value to our clients through a close relationship, advice on the interpretation of results and the preparation of clear and understandable reports.

AIMPLAS ensures the best results and quality for its clients so that companies can guarantee the reliability of their products or services