NIAS and How to Handle Them

Commission Regulation (EU) No. 10/2011 on plastic materials and articles intended to come into contact with food introduces the concept of NIAS in Preambles 18 and 20. They indicate that substances used in the manufacture of plastic materials and articles may contain impurities originating from their manufacturing or extraction process, and that, during manufacture and use of these materials and articles, reaction and degradation products may be formed.

These impurities and reaction and degradation products are non-intentionally added substances, or NIAS. The preambles go on to state that the main NIAS should be included in the risk assessment of the substances introducing them, which may entail establishing some restrictions or specifications of the substance, as in the case of these specifications:

Chlorofluoromethane content less than 1 mg/kg of the substance.

![]()

SML expressed as sum of its hydrolysis products.

NIAS Regulation

In both cases (impurities and reaction and degradation products), it is not possible to list and consider all the substances that may be present from this source, so many of them may not have been included in the Union list, though this need not imply that their presence should be banned. That is why in Article 6, “Derogations for substances not on the Union list”, of Regulation (EU) No 10/2011, non-intentionally added substances are included in Point 4 as substances not included in the Union list which may be present in the plastic layers of plastic materials and articles. However, the same regulation provides that compliance with the requirements of Article 3 of Regulation (EC) No 1935/2004 (non-transfer of components that are toxic or that alter food composition or organoleptic characteristics) must be assessed based on internationally recognized scientific principles on risk assessment.

The topic of NIAS was therefore already included at the time of publication of the 2011 regulation, but only recently have concerns about NIAS increased. This was the result of the identification of potentially hazardous chemicals migrating from the plastic materials and articles intended to come into contact with food due to the improved sensitivity of chemical analysis methods.

It is therefore very clear that there is a need to assess NIAS associated with substances.

How do we do it?

A NIAS study involves three steps:

- Drawing up a list of predictable NIAS from process information: In specific stages of the production chain, NIAS can be fairly easily predicted based on previous experience and/or theoretical chemistry. Transferring this information throughout the supply chain greatly facilitates the identification and subsequent risk assessment of NIAS. Because NIAS can continue to react in subsequent processing steps, it is also important to transmit relevant information to the upstream and downstream supply chain.

- Chemical analysis: Chemical analysis in this case is very complex, given that the aim is to detect and quantify, as far as possible, the (mostly unknown) substances migrating from the material or article. Bearing in mind that an estimated tens of thousands of possible substances migrate from materials and articles intended to come into contact with food, the lack of analytical standards for many of these substances, the fact that many of these substances (e.g. oligomers) are not included in chemical or spectral databases, and the challenge residing in the fact that there is currently no harmonized industry-wide methodology for dealing with NIAS, this analysis is very complex and requires very sophisticated equipment and highly specialized personnel.

- Risk assessment: Risk assessment is carried out sequentially, starting with a search for existing toxicity data on the identified substance (e.g. in common and national legislation, toxicity reports).

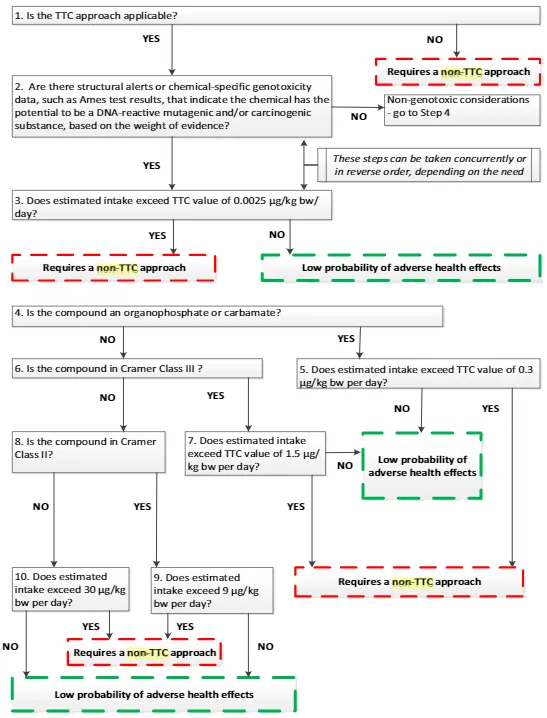

If we do not find data in these sources, we can apply the threshold of toxicological concern (TTC) approach, provided that the characteristics of the substance do not rule out the use of this approach.

The TTC approach is a pragmatic and scientifically valid methodology for assessing the safety of substances of unknown toxicity found in food and the environment. It is applicable to any substance with known structure that is not classified in excluded chemical categories, for which oral exposure can be estimated. In this approach, one of the five possible TTC values is assigned based on the chemical characteristics of the substance. The TTC value corresponds to the exposure level below which it can be concluded that there is a low probability of adverse health effects.

When the level of exposure is higher than the assigned TTC value or substance characteristics rule out the TTC approach, more specific methods must be used.

Operator responsibility for NIAS

There are currently no established migration or exposure levels to ensure compliance with safety requirements. It is therefore the responsibility of the food packaging producer and/or the food packager to perform risk assessment and define the level below which migration of NIAS does not pose a threat to human health. A business operator whose process generates NIAS must describe them and transfer the information to the next operator along the packaging manufacturing chain. Otherwise, the operator should automatically take on the job of verifying compliance with the safety requirements of the NIAS in question.

How are Spanish SMEs dealing with NIAS?

The topic usually arises as a requirement from customers, mainly large supermarkets and food companies, rather than from the competent authorities.

SMEs are often unaware of the matter and their obligations. When they try to address the issue, they have problems getting information on possible NIAS from previous processes due to confidentiality issues. Moreover, the cost of doing a proper NIAS study is very high and becomes even more expensive when information from suppliers is lacking.

AIMPLAS offers companies personalized advice so that they can comply with the different regulations and protocols in the field of plastics. Do not hesitate to contact us if you need help adapting to current legislation.

Chromatography Group