Life Cycle Assessment

A life cycle assessment (LCA) provides companies with a strategic opportunity to identify areas for improvement in sustainability and efficiency.

A Life Cycle Assessment (LCA) is an environmental assessment methodology that involves analysing and quantifying a product’s environmental aspects and potential impacts (e.g. resource use and the environmental consequences of emissions) over its entire life cycle, i.e. from raw material acquisition through production, distribution, use and end-of-life disposal or recovery.

Benefits of doing a Life Cycle Assessment

AIMPLAS experts offer advice on determining the environmental impact of plastic products and related services throughout their life cycle in accordance with the standardized methodologies described.

- An LCA helps identify opportunities to make environmental improvements to products at different stages in their life cycle, thus reducing their impact and making them more environmentally friendly.

- It provides company decision makers with information for strategic planning and the ecodesign of products and processes.

- Using the life cycle approach is mandatory for companies certified under the ISO 14001 standard or applying for certification.

- An LCA helps companies obtain environmental labels and certificates, such as Environmental Product Declarations (EPD) and carbon footprint certificates.

- It enables companies to implement ecological marketing strategies.

- An LCA improves brand image and value.

- It provides access to Green Public Procurement processes.

LCA Phases

According to reference standards ISO 14040 and ISO 14044, an LCA study comprises four retrofit phases:

- Goal and scope definition.

- Life cycle inventory (LCI).

- Life cycle impact assessment.

- Interpretation.

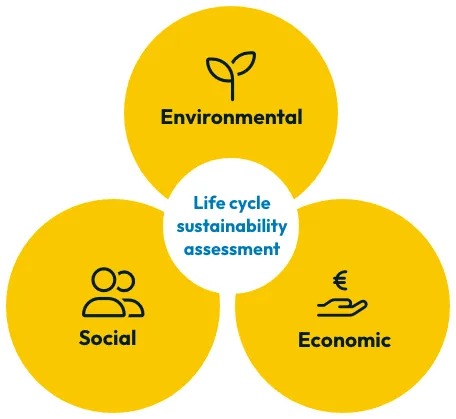

Sustainability analysis from a life cycle perspective

A life cycle sustainability assessment is composed of 3 studies:

- Environmental analysis: life cycle assessment (LCA). It assesses the environmental impact throughout the life cycle of the product, process, or activity.

- Economic analysis: life cycle costing (LCC). It assesses potential economic impacts.

- Social analysis: social life cycle assessment (S-LCA). It assesses social impacts.

What is a Life Cycle Costing?

A Life Cycle Costing (LCC) is a methodology for the systematic evaluation of the economic costs associated with the entire life cycle of a product or process, including not only direct costs but also external relevant costs and benefits (related to environmental externalities). LCC also follows a life cycle approach as in LCA, but it assesses the economic cots of the product or process instead of the environmental impacts.

What is a Social Life Cycle Assessment?

A Social Life Cycle Assessment is a methodology to assess the social and socio-economic aspects of products or processes and their potential positive and negative impacts along their life cycle. The aspects assessed in S-LCA are those that my directly or indirectly affect stakeholders, including workers, local community, consumers, value chain actors and society. S-LCA also follows a life cycle approach, but the impacts in this case are related to socio-economic processes and comprise human rights, working conditions, health and safety, socio-economic repercussion, and so forth.