Exploring the impact of temperatures on mechanical properties

Polymers can be used in several applications, but their mechanical properties can significantly be altered under extreme temperatures. Understanding their performance in sub-zero or elevated temperatures is crucial as polymers exhibit varied responses, influencing their reliability and functionality in various applications. Given the temperature-dependent nature of material properties and the expectation of usage across different temperature ranges, it prompts the question: Why should we settle for an industry that provides material properties solely at specific temperatures?

The automotive industry serves as a prime example wherein plastic components like seals and connectors encounter diverse temperature ranges throughout their lifespan. These varying temperatures demand distinct behaviors: in low temperatures, flexibility and impact resistance are essential to prevent rigidity, while at elevated temperatures, the emphasis shifts towards dimensional stability and thermal resistance. Ensuring these properties is vital to prevent deformation and ensure long-term reliability. Understanding this thermal duality is pivotal for comprehending and characterizing the mechanical properties of polymers under different real-world conditions.

When subjected to low temperatures, certain materials may become brittle, whereas others exhibit remarkable resilience. This fundamental understanding is key to comprehending polymer behavior in cold environments. Conversely, high temperatures pose challenges to polymer resistance, often resulting in alterations in flexibility. Such insights are crucial for accurately predicting material performance under elevated temperatures.

As an example, the figure below illustrates the relationship between stress, strain and temperature, in order to understand these behavioral shifts:

Figure 1. Stress-strain curve of a Polyamide 6 (PA-6) at different temperatures.

This graph clearly shows that the mechanical properties of these materials drastically change according to temperature and that the same materials lose resistance and stiffness as temperature rises.

The second figure illustrates the variation of one of the most relevant tensile properties such as the Young Modulus (E) with the temperature of two technical polymers such as polycarbonate (PC) and polyamide 6 (PA-6).

Figure 2. Variation in the elasticity at various temperatures.

As depicted, polymers exhibit non-uniform responses to temperature fluctuations, meaning materials with high modulus at room temperature can rapidly lose these properties as temperature increases. Generally, thermoplastics undergo significant changes in rigidity and tenacity, whereas thermoset plastics typically maintain their properties across various temperature ranges.

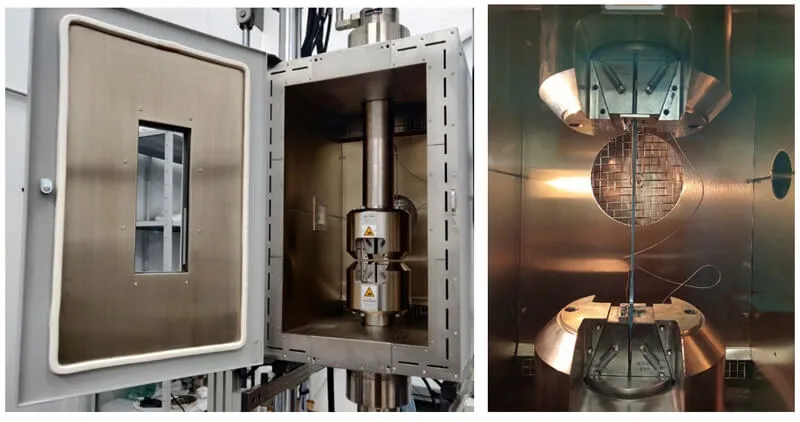

Figure 3. Temperature chamber with a system with clamps for testing traction properties.

How can AIMPLAS help your company?

In conclusion, comprehending the effects of temperature on the mechanical properties of polymers opens up a spectrum of opportunities for innovation and practical application. At AIMPLAS, we embrace the exploration of the inherent complexity of polymer materials. Conducting tests across a range of temperatures, from -70 °C to +250 °C, we utilize our temperature chambers for tensile, compression, and bending tests in compliance with ISO and ASTM regulations. This integrated system ensures efficient and reliable management during testing, guaranteeing quality and precision.