Classification and identification of plastics

According to their characteristics, there are three types of classifications regarding plastics according to: their chemical structure, their polarity and their applications.

According to their chemical structure and temperature behaviour, plastics can be divided into:

- thermoplastics

- thermosets

- elastomers

With regard to polarity, the presence of atoms of a different nature causes electrons to move towards the most electronegative atom in covalent bonds, thus resulting in a dipole. Polymers containing these extremely electronegative atoms, such as CI, O, N, F, etc., will be polar compounds, which has an effect on the properties of the material.

If the polarity is increased, the mechanical resistance, hardness, rigidity, heat resistance, water and moisture absorption and chemical resistance, as well as permeability to polar compounds such as water vapour and adhesivity and adherence to metals is also increased. At the same time, the increase in polarity reduces the thermal expansion, the electrical insulation capacity, the tendency to accumulate electrostatic charges and the permeability to polar molecules (O2, N2). In this way, it is possible to distinguish between different families such as polyolefins, polyesters, acetals, halogenated polymers and others.

Types of plastics

Polyethylene terephthalate (PET or PETE) 2. High density polyethylene (HDPE) 3. Polyvinyl chloride (PVC) 4. Low density polyethylene (LDPE) 5. Other plastics (polycarbonate, styrene, nylon, etc.).

The third and last classification, according to their application, is applied to thermoplastic materials. There are four types of plastics:

- Standard plastics or commodities: plastics manufactured and used in large quantities due to their price and good characteristics in many ways. Some examples are polyethylene (PE), polypropylene (PP), polystyrene (PS), polyvinyl chloride (PVC) or the copolymer acrylonitrile butadiene styrene (ABS).

- Engineering plastics: used when good structural, transparency, self-lubrication and thermal properties are needed. Some examples are polyamide (PA), polyacetal (POM), polycarbonate (PC), polyethylene terephthalate (PET), polyphenylene ether (PPE) and polybutylene terephthalate (PBT).

- Special plastics: They have a specific property to an extraordinary degree, such as polymethyl methacrylate (PMMA), which has high transparency and light stability, or polytetrafluoroethylene (Teflon), which has good resistance to temperature and chemical products.

- High-performance plastics: mostly thermoplastic with high heat resistance. In other words, they have good mechanical resistance to high temperatures, particularly up to 150°C. Polyimide (PI), polysulfone (PSU), polyethersulfone (PES), polyarylsulfone (PAS), polyphenylene sulfide (PPS) and liquid crystal polymers (LCP) are high-performance plastics.

Identification of plastic materials

With regard to the identification of plastics, there are different reasons that lead to the need for performing analyses of plastic materials:

- to check compliance with the technical data sheet of a raw material,

- to check the specifications or technical requirements of an injected part,

- to find the source of a behaviour failure of a complex food packaging film, to identify a foreign body found in a foodstuff,

- to do reverse engineering of an unknown material,

- etc.

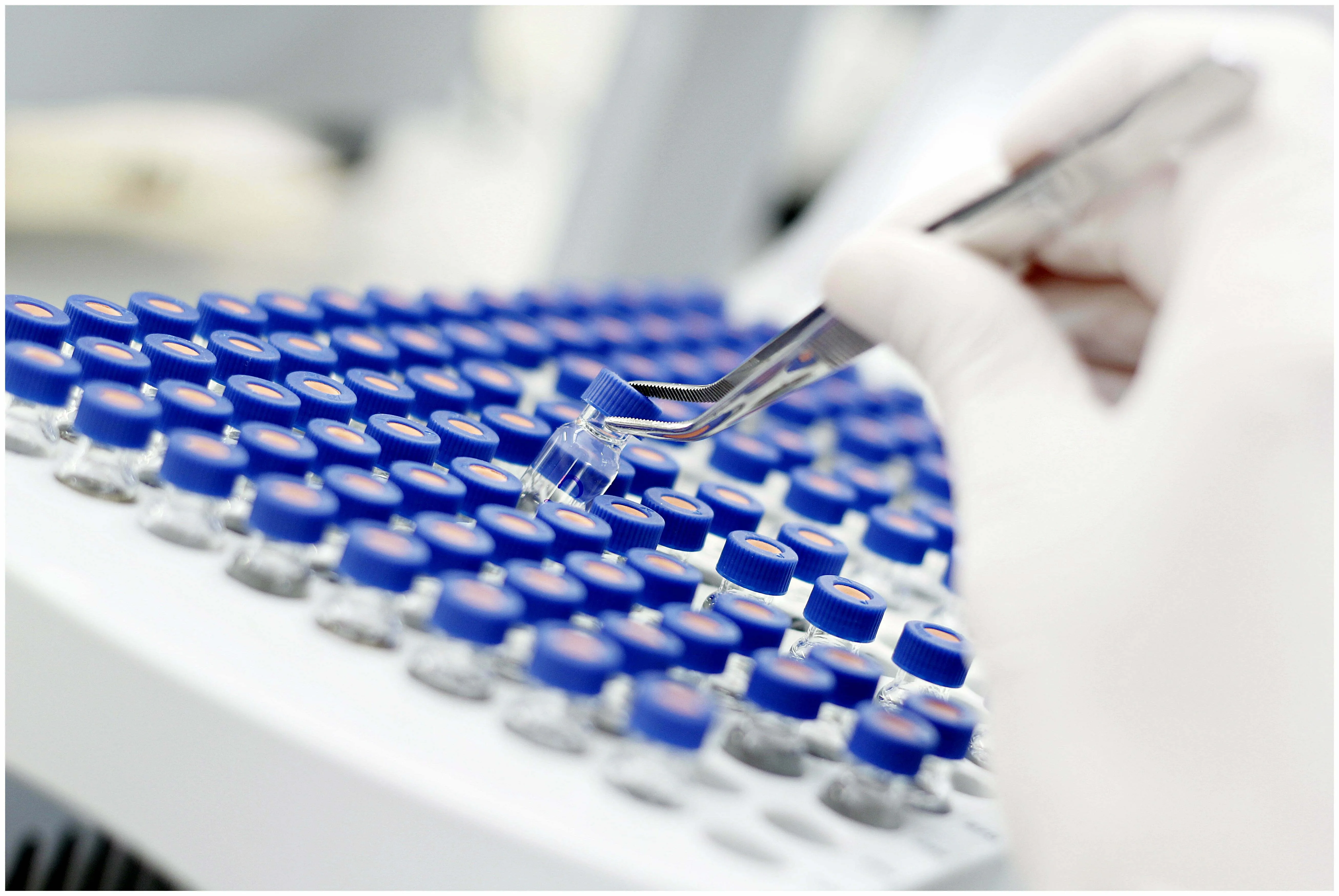

In all these cases, AIMPLAS’ laboratories have the perfect combination between highly experienced experts and cutting-edge technologies to cover any need on the identification of plastic materials, from raw materials, semi-finished and finished products to wastes and recycled materials obtained after their first use.

Our analysis capabilities cover all the application industrial sectors related to plastic materials: packaging (food, pharmaceutical, industrial, etc.), automotive and transport, construction, medicine, agriculture, aeronautical industry, electronics, leisure and sports, furniture, etc.

Analysis techniques

The main analysis techniques performed by AIMPLAS’ laboratories are:

- Infrared Spectroscopy (FTIR): it allows us to obtain a fingerprint spectrum specific of each material that, thanks to the knowledge and the existing databases gives us information about the base polymer of any plastic material, as well as other components present in the material (mineral fillers, copolymers, polymer blends, etc.).

- Differential Scanning Calorimetry (DSC): thermal analysis technique that allows us to obtain the thermal transitions produced during the heating of the analysed material specific for each material and provides information additional to that obtained by FTIR, thus complementing the identity of a polymeric material.

- Thermogravimetric analysis (TGA): another thermal analysis technique resulting in quantitative information about the composition of a plastic material regarding polymer percentages, other organic components, mineral fillers, carbon black, etc.

- Capillary and rotational rheometry: they allow us to determine the rheological properties of polymeric materials by measuring their creep and deformation resistance. The rheological analysis of these materials provides us with essential information on processability as well.

- Optical and scanning electron microscopy (SEM): provide information about the structure of the materials analysed regarding the number and thickness of layers in multilayer materials, dispersion size of pigment or filler particles in the polymeric matrix, coating defects, interphase morphology between components, etc.

- Chromatography (LC-PDA, LC-MS, LC-LS, GC-MS, GC-FID, HS-GC): thanks to chromatographic analyses we can quantify the minor components of plastic materials, such as UV stabilizers, antioxidants, plasticisers, anti-slip agents, etc. as well as residual monomers, residual solvents from inks or adhesives, degradation substances, etc. to check compliance with the legislation, manufacturer specifications or international standards required by users.

We have the necessary equipment for all of the applications mentioned above. We are different to others because we offer our clients an exquisite, highly personalized service, getting them involved in the solution, and working as a team.

Our experts in chemical analysis and identification can help to resolve any of your queries about plastic material analyses.