Thermomechanical Analysis (TMA): Dimensional Behaviour of Plastic Materials

Thermomechanical analysis (TMA) is a fundamental technique for measuring the dimensional changes of plastic materials under controlled conditions of force, atmosphere, time, and temperature. These changes are directly related to the viscoelastic properties of the material, which influence its response to mechanical stresses at various temperatures. In this article, we explore how TMA can help measure key properties such as softening temperature, glass transition temperature, melting point and the coefficient of thermal expansion (CTE).

AIMPLAS now has a new thermomechanical analyser that enables the measurement of key properties such as softening temperature, glass transition temperature, melting point and contraction and expansion coefficients (CTE). Following international standards such as ISO 11359-2 and ASTM E831, the dimensional changes of samples—whether contraction or expansion—are measured as they are heated or cooled. Understanding these values is critical for determining how a material expands or contracts at various temperatures, which is essential for identifying potential failures in products used under specific thermal conditions.

From graphs like the one below, which represent the dimensional change of the specimen as temperature increases for a given material, it is possible to calculate the linear coefficient of thermal expansion and the mean coefficient of thermal expansion using equations (1) and (2), respectively.

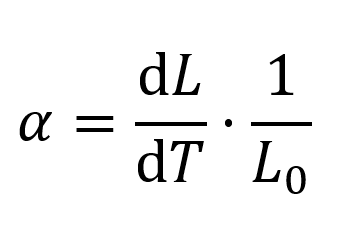

The linear coefficient of thermal expansion (α) is obtained using equation (1).

Where L is the length of the specimen in micrometres, L₀ is the initial length of the sample in micrometres at room temperature, and T is the temperature in kelvins.

Equation 1

The mean linear coefficient of thermal expansion (α) is calculated using equation (2).

Equation 2

Where α is the mean coefficient of thermal expansion, ΔT is the expansion of the sample in micrometres over a specified temperature range, L₀ is the initial length of the sample in micrometres at room temperature, and ΔL is the temperature change in kelvins during the test. The value of the thermal expansion coefficient depends on the material and the temperature range analysed. The measurement of the linear coefficient of expansion can be performed in different injection directions, allowing for an analysis of differences in expansion along the longitudinal, transverse, or perpendicular directions to the plane.

Thanks to this equipment, tests for tensile, penetration, and bending can also be performed. The tensile test for films allows for the analysis of stress-strain graphs, particularly in cases where low forces are applied, as well as dynamic tension tests to determine viscoelastic parameters such as storage modulus (E’), loss modulus (E’’), and tan (δ). This test can also be performed using a dynamic mechanical analyser (DMA). Additionally, the penetration probe can determine softening and glass transition temperatures according to ASTM E1545 and ISO 11359 standards. These measurements are useful, for example, for coating characterisation or determining the softening temperature of each polymer in polymer blends.

If you are interested in obtaining these measurements, do not hesitate to contact us.