Membranes

Membranes offer a wide range of possibilities and advantages in the development of more sustainable processes for separating greenhouse gases and storing energy.

Membrane applications are widespread at industrial level, mainly for purification processes. However, new lines of research have emerged, such as energy storage, gas separation and even the creation of biosensors, which allow membranes to be classified as high value-added products.

Membrane applications

Gas separation to reduce the greenhouse effect

The use of membrane technology is a promising way to fight climate change by reducing greenhouse gases such as CO2 and methane. Membranes are able to selectively separate different types of gases that can be used to generate higher value-added products. The membranes most widely used commercially separate O2/N2, CO2/CH4, H2/N2, He/air and H2/CH4. This technology is used in a variety of applications such as hydrogen separation in ammonia production plants, nitrogen production, natural gas enrichment (separating CO2 from CH4), dehydration of air and natural gas streams, helium recovery, gasoline recovery and pervaporation.

Energy storage

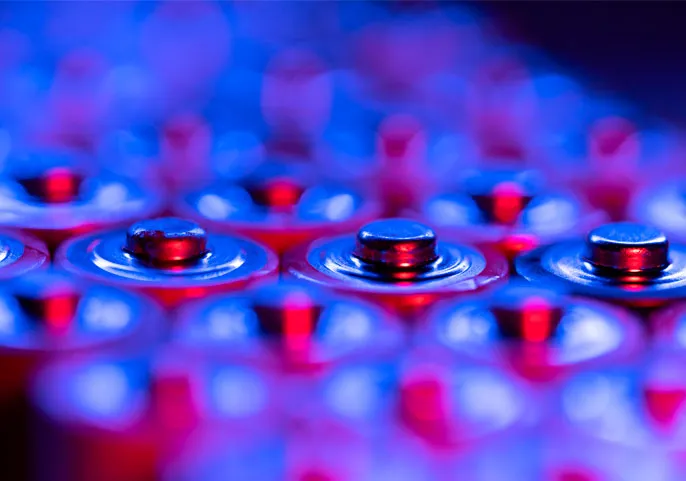

Metal-air batteries have attracted particular attention due to their semi-open structure, which uses inexhaustible oxygen from the air as an oxidant, thus resulting in a high theoretical energy density.

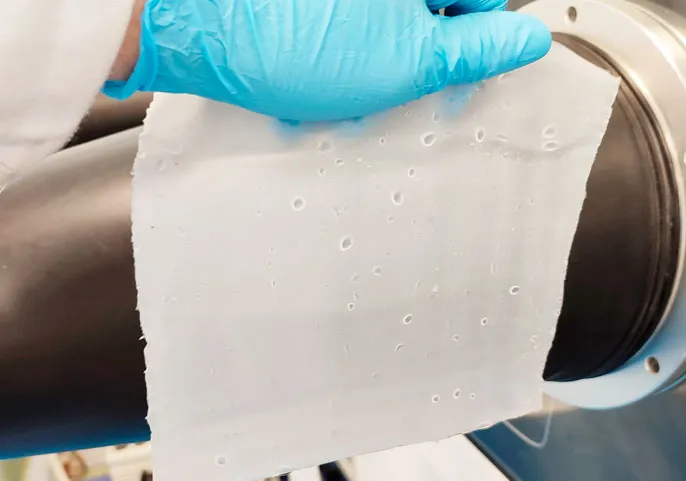

Membranes play a key role in battery manufacturing because they are able to transport ions between electrodes to create a physical barrier and prevent short circuits. These membranes must have high structural strength, chemical stability and high ionic conductivity to guarantee the battery’s long-term safety and reliability.

Celgard membranes are widely used commercially in Zn-air batteries due to their good chemical stability and low cost. However, they exhibit increased cell polarization, resulting in battery capacity fade. Addressing this challenge involves developing different types of membranes, including anion and cation exchange membranes (AEMs/CEMs), composite membranes and electrospun nanofibre membranes. In this regard, Aimplas started to work within the framework of the ACUMULAREQ project on the development of bio-based polymeric membranes for use as separators in metal-air batteries.

Water treatment

Membranes are widely used in effluent treatment processes. Several research projects have been carried out on wastewater treatment to obtain better purification performance and reduce operating and maintenance costs through processes that are highly flexible and can withstand variations in the effluent while producing as little sludge as possible. Membranes are also often used in pharmaceutical applications, where they are able to separate proteins and lipid and polymeric nanoparticles in the effluent, among other substances.

The most commonly used membrane processes in wastewater treatment include electrodialysis, microfiltration, ultrafiltration, nanofiltration and reverse osmosis. Commercially available membranes based on polysulfones and fluorinated polymers with polypropylene are widely used for this kind of application.

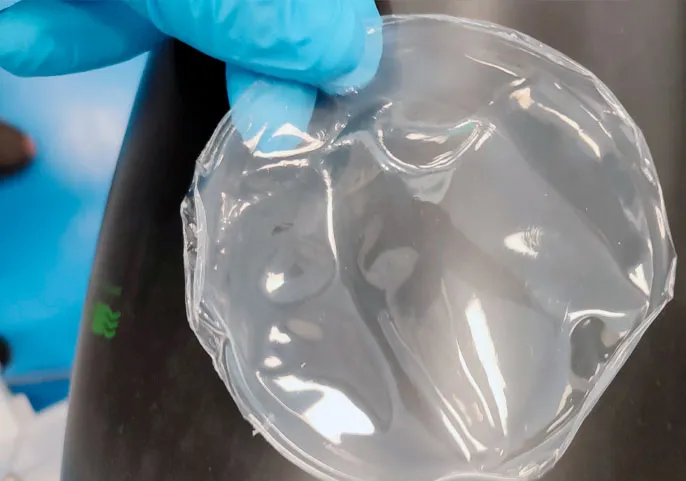

Reverse osmosis membranes

Reverse osmosis is one of the most common processes in water treatment. It involves removing pollutants from water by reducing the flow to be treated, which passes through a semi-permeable membrane at a pressure greater than osmotic pressure in the opposite direction of the osmosis process. The substances in the water are thus separated on one side of the membrane (concentrate) and a diluted solution low in dissolved solids (permeate) is on the other side.

Electrodialysis

Electrodialysis is a technique based on the transport of ions through selective membranes via application of an electric field. These membranes must contain uniformly distributed negatively and positively charged ions. Because this technique requires a continuous electric field, the separation process must be carefully optimized. Dialysis can be applied in the food, chemical and textile industries, among others, and is commonly used for water treatment.

Catalysts

Catalytic membranes are seen as an attractive alternative in several processes such as hydrogen production.

Membranes doped with palladium and its alloys lead to higher reaction conversion and hydrogen selectivity, and provide faster conversion because methane is in direct contact with the catalyst and the selective film.

Platinum-doped membranes are used for hydrogen energy storage in fuel cells. Zeolite membranes are also able to produce hydrogen, methanol and dimethyl ether, and can even be used for isobutane dehydrogenation, among other applications.

Biosensor development

The development of biosensors has been a major challenge due to the importance of their stability and specificity. It has therefore been necessary to develop porous materials such as synthetic membranes that are able to act as an electrical circuit of resistors and capacitors in conjunction with the electrode and detect specific compounds, such as pathogens, glucose and bisphenol A, thanks to their high sensitivity, reversibility, measurement speed and selectivity.

Sensing membranes perform two main functions: on the one hand, they immobilize sensitive elements (e.g. enzymes, antibodies) and complementary elements (e.g. plasticizers, coenzymes, nanoparticles), and, on the other hand, they separate by acting as a barrier to any interference that could modify the analytical signal. They can therefore be applied in clinical, biomedical and environmental applications, among others.

AIMPLAS experience in membrane applications

We carry out R&D projects in which membranes offer a wide range of possibilities and advantages in the development of more sustainable processes in the separation of greenhouse gases and energy storage.

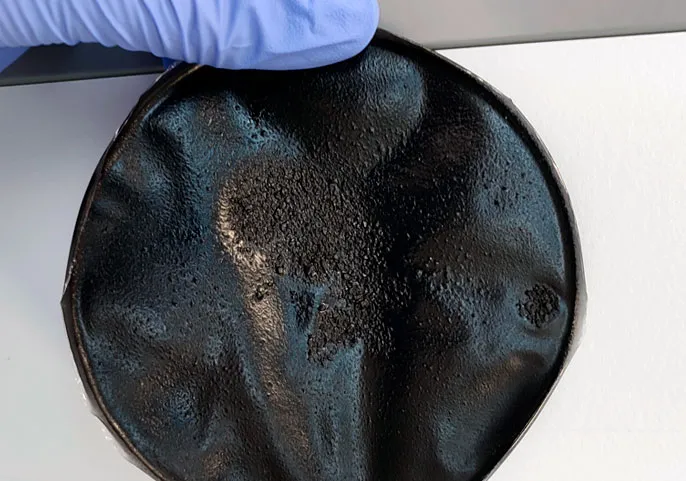

The challenge posed by the use of membranes in processes for recovery of compounds such as methane in liquid streams has driven research on surface modification of these films using physical and chemical processes to increase their selectivity and even provide them with hydrophobic properties.

Of particular interest is the development of processes that involve improvement of the circular economy. Work is therefore being carried out on projects to separate and capture CO2 from industrial emissions via innovative processes that involve the use of porous materials such as MOFs and zeolites in combination with membrane technology.

Among the developments carried out by Aimplas, it is worth mentioning the elimination of 94% of the drug present in an aqueous stream through the synthesis of MMMs in the Eternal project and the manufacture of membranes with good selectivity for the separation of CH4/CO2 or H2/CO2 produced in the MatenergyH2 project.