Food contact

Plastic materials in contact with food must comply with strict regulations to ensure food safety.

At AIMPLAS, we offer a comprehensive service that combines technical and legal advice, accredited testing, and specialised training to ensure food safety and regulatory compliance for materials and articles intended to come into contact with food, from their design through to marketing in both national and international markets.

Our multidisciplinary team guides you through the application of the European and international legal framework, assessing both conventional and bio-based or recycled materials. We design studies tailored to real or simulated conditions of use, and help you interpret results, identify risks, and make key decisions in the development, reformulation, or approval of your products.

Food Contact Materials Solutions:

- Comprehensive regulatory advice

- Migration and substance control testing

- Barrier and functional properties assessment

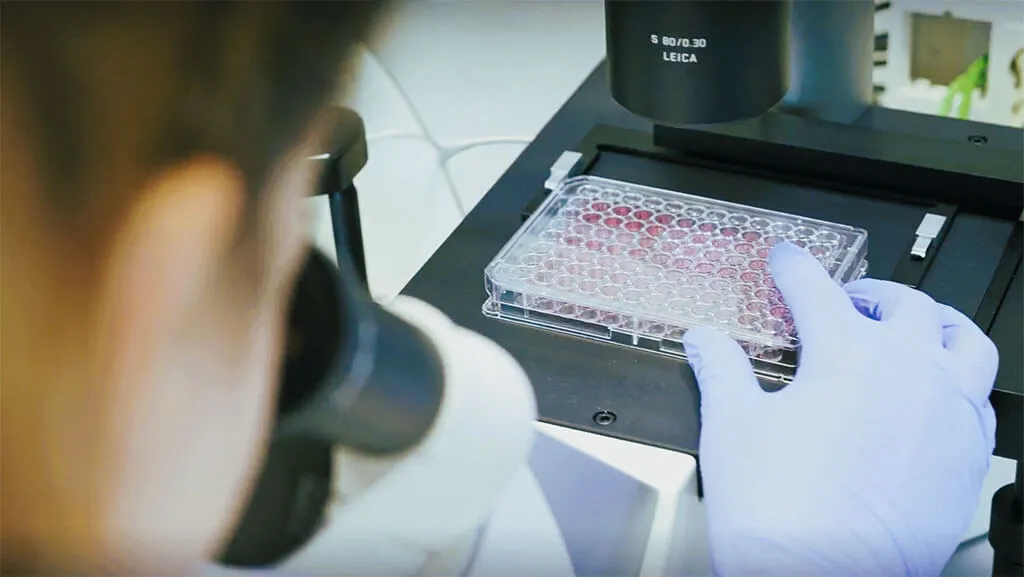

- Toxicological evaluation and in vitro bioassays

- Auditing and testing for materials in contact with drinking water

- International regulatory compliance

- Reusability certification – Designed to be reusable

- Specialised training and advisory services

Comprehensive regulatory advice

We offer guidance to ensure compliance with European legislation, including general regulations such as Regulation (EC) No 1935/2004, which establishes the principles of safety and inertness for all food contact materials, and Regulation (EC) No 2023/2006 on good manufacturing practice. We also address specific legislation such as Regulation (EU) No 10/2011 for plastic materials and Regulation (EU) No 1616/2022 for recycled plastics. In addition, we cover applicable legislation for materials such as ceramics, paper, metals, active and intelligent materials, and printed inks.

Internationally, we offer expert advice to comply with regulations such as FDA 21 CFR in the United States.

In Japan, we follow the Food Sanitation Act administered by the Ministry of Health, Labour and Welfare (MHLW). We review the Positive Lists (PL) under this law, updated on 30 November 2023, which came fully into force on 1 June 2025. This includes both permitted polymers listed in Table 1 and the maximum additive limits in Table 2 of the Japanese positive list.

For China, we apply the Chinese Food Contact Material Standards, including the General Safety Requirements for FCMs and the Standard for the Use of Additives in FCMs.

We also provide regulatory advice in frameworks such as MERCOSUR (GMC) and other technical standards including BfR recommendations (Germany), the Swiss Ordinance on inks and adhesives, and the EDQM guide for metallic materials.

Furthermore, if your product is intended for other sectors, we provide support for compliance with:

- Directive (EU) 2020/2184 on materials in contact with drinking water

- Regulation (EC) No 1223/2009 on cosmetic products

- Regulation (EU) 2017/745 on medical devices

- Pharmaceutical packaging regulations such as the European Pharmacopoeia and the US Pharmacopeia (USP)

We also support the implementation of the new European Safe and Sustainable by Design (SSbD) principles, including more sustainable toxicological assessment approaches and in vitro bioassays.

Our team will assess your product, define the applicable regulatory framework, and help you prepare all the necessary technical documentation (declarations of compliance, technical dossiers, certificates, etc.) so you can market it with full legal assurance.

Migration and substance control testing

We have ENAC-accredited laboratories under UNE-EN ISO/IEC 17025, where we carry out specific tests to ensure the safety and compliance of materials intended for food contact.

We perform overall and specific migration studies in accordance with standards such as EN 1186 and EN 13130, and determine the presence of residual monomers, additives, contaminants, and other substances of concern. We also use non-targeted screening methodologies to identify NIAS (Non-Intentionally Added Substances).

In addition, we offer testing services to demonstrate compliance with international regulations such as FDA (21 CFR) for the US market and Japanese legislation under the Food Sanitation Act.

You can also consult our specific service for testing materials in contact with drinking water, with a focus on Directive (EU) 2020/2184 and other international standards.

Barrier and functional properties assessment

We carry out specific studies to determine barrier properties against oxygen (OTR), water vapour (WVTR), and CO₂, which are key to food preservation and shelf-life extension.

We assess dishwasher resistance using tests according to UNE 53928 (ENAC accredited) and UNE-EN 12875, verifying reusability, cleanability, and durability. We also test microwave resistance according to EN 15284. Food compatibility is verified under UNE 53975, and we perform sensory testing according to UNE-ISO 13302 to ensure no alteration in food taste or odour.

We also conduct leak testing (ASTM F3039, F1929 and D3078) and child-resistant closure testing accredited to UNE-EN ISO 8317. The Cobb test with water and oil is also available, following UNE-EN ISO 535:2014, especially relevant for reusable or heavy-duty packaging.

Additionally, we offer technical certification for reusable packaging, assessing strength, durability and safety in line with current legislation and circular economy demands.

Toxicological evaluation and in vitro bioassays

We help ensure the toxicological and environmental safety of your materials, particularly recycled or bio-based ones, through a specific line of in vitro bioassays for risk assessment, including micro- and nanoparticles or emerging contaminants.

We apply EFSA principles, OECD guidelines, and the European SSbD framework, evaluating biocompatibility and potential adverse effects.

We carry out:

- Cytotoxicity testing (ISO 10993-5)

- Genotoxicity testing (OECD 471, 487, 489)

- Ecotoxicity tests on plants (OECD 208), fish, and soil bacteria

- Oxidative stress testing

We also develop gastrointestinal digestion studies for nanomaterials and microplastics, and apply advanced cell models for more accurate and sustainable toxicological characterisation.

Auditing and testing for materials in contact with drinking water

We support you in ensuring the safety, purity, and regulatory compliance of all materials and components intended for contact with water for human consumption, offering advisory services in accordance with Directive (EU) 2020/2184 and complementary Regulations 2024/367–371.

We conduct technical audits, material and substance reviews, migration tests, compound identification, and compliance assessments to help you meet legislative requirements and bring safe, compliant products to market.

International regulatory compliance

We help you adapt your materials to the regulatory requirements of key global markets. We guide you in applying the FDA 21 CFR regulations in the US, assess your product according to Japan’s Positive List under the Food Sanitation Act, and work with the relevant GB Standards for Chinese legislation.

We also prepare technical documentation, declarations of compliance, and assist you in regulatory audits, ensuring your product meets all legal requirements for international marketing.

Reusability certification – Designed to be Reusable

At AIMPLAS, we have developed a new voluntary European certification mark that guarantees a product has been conceived, designed, and marketed to be safely reusable in contact with food.

We certify key aspects such as food safety, wash resistance, durability, REACH compliance and critical substances, weight and volume limits, functionality, and end-of-life. This certification helps your product stand out from competitors and offers consumers reassurance about its reusability. It also contributes to waste reduction and promotes recycling and recovery, aligning with circular economy goals.

Specialised training and advisory services

We offer tailored, up-to-date technical training on European and international legislation for food contact materials, migration and NIAS testing, toxicological evaluation, bioassays, safety of recycled materials, and good manufacturing practices.

We adapt our courses, webinars, and workshops — both in-person and online — to the specific needs of your company, so you stay informed and compliant with current legislation.

At AIMPLAS, we help ensure that your food contact materials comply with legislation, are safe, and meet market demands. From development to market placement, we turn regulatory complexity into clear solutions, making your product safe, compliant, and distinctive.