Additive Manufacturing Drives Advances in Soft Robotics

Soft robotics is a rapidly growing branch within the field of industrial robotics. Unlike traditional robots made from rigid materials, soft robots are constructed from flexible and deformable materials, allowing them to adapt and operate in dynamic and variable environments more safely and efficiently. One of the key areas driving advancements in soft robotics is the application or combination of this technology with additive manufacturing. The key features of soft robots include:

- Flexibility and Adaptability: Their ability to deform and adapt to various shapes and surfaces.

- Safety: Their soft nature makes them safe for interacting with humans and delicate environments.

- Customization: The ability to design robots specific to particular tasks thanks to the versatility of materials and manufacturing techniques.

Applications of Soft Robotics

Soft robots have a wide range of applications across various fields, from medicine to space exploration. Some of the most interesting applications include:

- Medical Applications: Soft robots are ideal for interacting with delicate biological tissues. They are often inspired by biomechanical characteristics, making them perfect for medical applications like minimally invasive surgery, rehabilitation, or assisting people with reduced mobility through wearables.

- Hazardous Environment Manipulation: Due to their ability to adapt to variable environments and their safe nature for humans, soft robots are ideal for exploration and manipulation tasks in dangerous environments, such as underwater exploration, inspection of structures, or handling toxic or radioactive agents.

- Agriculture and Food Handling: In agriculture, soft robots can handle delicate products without damaging them, which is crucial for harvesting and food processing. The creation of customized grippers and manipulators that adapt to different shapes and sizes of agricultural products is highly versatile for this field.

- Collaborative Robotics: Soft robotics is indispensable in production lines. Unlike conventional hard robotics, soft robotics works side by side with humans in a safe and efficient manner, making them ideal for assistance applications in factories and warehouses.

Techniques and Materials Used in Soft Robotics via Additive Manufacturing

The manufacturing of soft robots benefits greatly from advanced additive manufacturing technologies, also known as 3D printing. Additive manufacturing has revolutionized the way soft robotics are designed and produced, enabling greater customization, flexibility, and efficiency in production. Some of the additive manufacturing techniques used in soft robotics include:

- Printing Flexible Materials: Additive manufacturing using fused filament/pellet fabrication (FDM/FGF) allows the creation of complex structures with flexible materials such as thermoplastic elastomers (TPU/TPE) or silicones (PDMS), which can stretch and deform significantly without breaking—essential for soft robot manufacturing. Hydrogels, materials capable of absorbing large amounts of water and changing shape, are also used in medical and biological applications, providing greater adaptability and functionality to the technology’s fields of use.

- 4D Printing of Materials: These materials can change their characteristics, such as shape, structure, or functionality, in response to external stimuli like temperature, humidity, light, electric current, or even magnetism. The integration of 4D materials in soft robotics opens new possibilities for creating adaptable and self-configuring robots that can change function based on the needs of the environment or task.

- Multi-Material Printing: The ability to print objects with multiple materials and additive manufacturing techniques, such as FDM and Direct Ink Writing (DIW), in a single operation enables the creation of structures with varied mechanical and functional properties. This is crucial for the production of soft robots with integrated actuators and sensors. The combination of “stretchable” inks, specially formulated to maintain their electrical and mechanical properties when subjected to deformation, is used to print electronic circuits. These inks, combined with conductive polymers loaded with carbon-based additives, are widely used to integrate electronic and sensory functions into soft robots, resulting in intelligent devices with sensing and actuation capabilities.

- Integration of Sensors and Electronics: Until recently, most soft robotics systems have relied on traditional rigid electronics to store control algorithms and connect to actuators, sensors, and power sources. However, recent efforts in the field of soft electronics aim to enhance the integration of this technology in actuator developments. The combination of flexible structural materials, functional 4D materials, and multi-material printing techniques allows for the direct integration of sensors, actuators, and electronic components into the structure of soft robots, simplifying the manufacturing process by reducing assembly complexity and adding advanced features and functionalities.

AIMPLAS and Soft Robotics

AIMPLAS is dedicated to advancing soft robotics, particularly through the SOFTRONIC Project, which merges various emerging additive manufacturing technologies to create intelligent devices that bridge these two worlds.

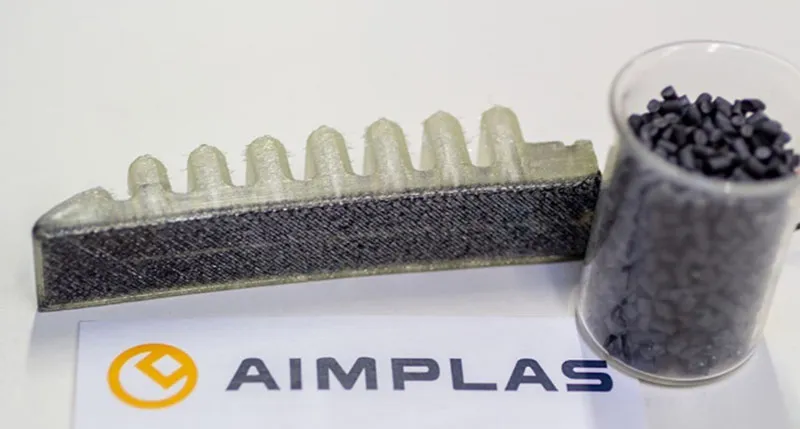

As part of this project, elastomeric polymers and electrically conductive polymers have been developed to manufacture pneumatic actuators with integrated electronics through a hybrid additive manufacturing process, thus optimizing the subsequent steps of embedding electronics.

Soft robotics demonstrator from the SOFTRONIC project carried out by AIMPLAS.

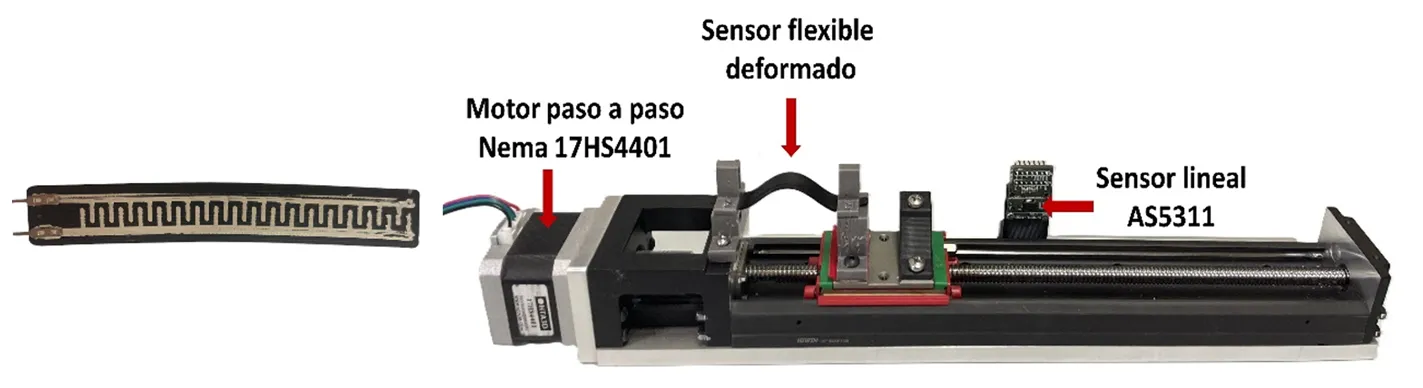

This innovation has led to the development of a pneumatic gripper equipped with integrated flex sensors. These sensors allow for pressure adjustments according to the object being handled, eliminating the need to change the type of gripper based on the object’s hardness. This streamlines the handling process between product batches.

Test bench for materials used in the electromechanical tests of the flexible sensor.

The electromechanical tests conducted by the Carlos III University of Madrid have demonstrated not only the advantages but also the areas for optimization of these flexible sensors. Primarily, improving linearity will directly influence a wider working range while maintaining high sensitivity. The results of this collaboration allow for continued work on optimizing these devices, aiming for their future integration into various soft robotic platforms [7] [8]. In this way, significant contributions are made toward advancing technology in this field and developing more adaptable and efficient soft robots, capable of performing complex tasks with greater precision and safety.

The Future of Soft Robotics and Additive Manufacturing

Soft robotics, with its ability to adapt to different environments thanks to flexible materials, is experiencing rapid growth in the industry, driven largely by its combination with additive manufacturing. Offering advantages such as customization, reduced material usage, and faster prototyping, this technology is revolutionizing the design and production of soft robots. Integrating flexible materials, functional 4D materials, multi-material printing, and even the direct incorporation of sensors and electronics into the structure of these robots is opening new possibilities in fields such as medicine, space exploration, and industry. Projects like SOFTRONIC, along with collaborations with universities such as Carlos III of Madrid, exemplify these advances. For further progress, it is crucial to continue research, foster interdisciplinary collaboration, and integrate other collaborative developments to drive innovation in this exciting technological field.

Daniel Rodríguez del Rosario | Additive Manufacturing expert in AIMPLAS

References

- Rus, D., & Tolley, M. T. (2015). Design, fabrication and control of soft robots. Nature, 521(7553), 467-475.

- Majidi, C. (2014). Soft robotics: a perspective—current trends and prospects for the future. Soft Robotics, 1(1), 5-11.

- Kim, S., Laschi, C., & Trimmer, B. (2013). Soft robotics: a bioinspired evolution in robotics. Trends in Biotechnology, 31(5), 287-294.

- Whitesides, G. M. (2018). Soft robotics. Angewandte Chemie International Edition, 57(16), 4258-4273.

- Shih, B., Lin, Z. C., & Suo, Z. (2012). Stretchable conductors as soft interconnects for dielectric elastomer actuators. Applied Physics Letters, 100(11), 114103.

- López-Valdeolivas, M., Liu, D., Broer, D. J., & Sánchez-Somolinos, C. (Year). 4D Printed Actuators with Soft-Robotic Functions. Journal Name, Volume(Issue), Page Range.

- Nagua L, Relaño C, Monje CA, Balaguer C. A New Approach of Soft Joint Based on a Cable-Driven Parallel Mechanism for Robotic Applications. Mathematics. 2021; 9(13):1468. https://doi.org/10.3390/math9131468

- Continelli, N. A., Nagua Cuenca, L. F., Monje, C. A. y Balaguer, C. . (2023) «Modelado de un cuello robótico blando mediante aprendizaje automático», Revista Iberoamericana de Automática e Informática industrial, 20(3), pp. 282–292. doi: 10.4995/riai.2023.18752.